What Every Driver Should Know About Engine Braking

Have you ever heard drivers complain that their engine brakes aren’t strong enough?

Some say their engine brakes don’t slow the truck down enough, so they have to rely on regular brakes. You may even see videos online suggesting that service brakes should be used to help with engine braking.

However, not everyone who advises on engine brakes fully understands how they work. Misinformation spreads quickly, and many drivers accept it without question. For example, one driver in a popular video seemed confused about why a truck’s engine brake wasn’t working well. He guessed it might be due to the muffler or that the engine brake itself was weak. In another video, the same person warned against letting the engine go above a certain speed, claiming it could damage the engine brake. However, experts disagree with these statements, and many drivers are misled by such incorrect advice.

What is an Engine Brake?

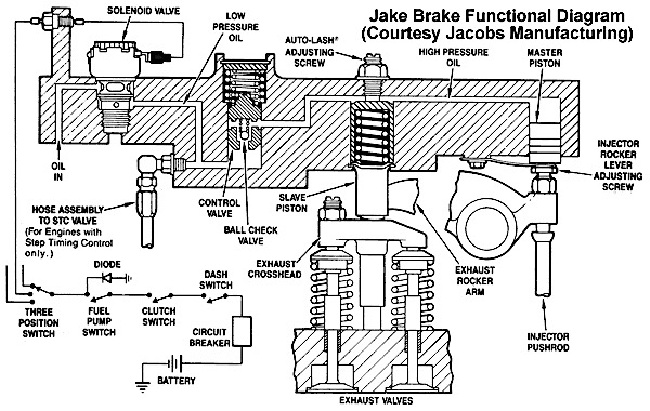

Despite its name, an engine brake isn’t a brake in the traditional sense. It’s called a “Compression Release Engine Brake,” a hydraulic system that changes the timing of the engine’s valves. This process temporarily turns the engine into an air compressor, slowing down the truck. These are often called “Jake Brakes,” though that’s just one brand name.

When the engine brake is on, it changes the way the engine cycles. Normally, a diesel engine goes through four strokes:

- Intake Stroke – The piston moves down, pulling air into the cylinder.

- Compression Stroke – The piston moves up, compressing the air.

- Combustion Stroke – Fuel is injected, causing an explosion that pushes the piston down and powers the truck.

- Exhaust Stroke – The piston moves up again, releasing exhaust gases.

With the engine brake on, the process changes:

- The intake and compression strokes stay the same.

- No fuel is injected, so no power is generated.

- At the top of the compression stroke, the exhaust valve opens, releasing the compressed air.

This prevents the engine from driving the wheels and instead absorbs energy from the truck’s momentum, slowing it down. That’s why engine brakes are sometimes called “retarders.” The loud popping sound engine brakes make is just compressed air escaping, though modern trucks have mufflers that reduce the noise.

Why Do Some Drivers Think Engine Brakes Are Weak?

There’s no such thing as a “weak” engine brake, but they can feel less effective if not used properly. Engine brakes work best at higher speeds (RPMs). Engineers have studied this and created charts showing that as engine speed increases, the braking power also increases. For example:

- At 1,200 RPM, an engine might produce 244 horsepower of braking power.

- At 2,200 RPM, the same engine could generate 630 horsepower of braking power.

This means if your engine brake isn’t slowing you down enough, you might be running it at an RPM that is too low. Some fleet managers tell drivers not to rev the engine high when using the brake, but engineers design

How to Get the Most Out of Your Engine Brake

One reason engine brakes may seem weak is modern trucks use “downsped” drivetrains, meaning they run at lower RPMs to save fuel. However, engine brakes don’t work as well at low RPMs. To increase braking power, drivers may need to shift down one or two gears.

Ideally, cruise control should help manage these downshifts automatically. But if cruise control isn’t used, the truck could pick up too much speed downhill, forcing the driver to use service brakes. Some fleets try to lock certain transmission settings to make drivers use cruise control, but if drivers aren’t familiar with the system, this can cause frustration.

Engine Speed and Braking Power

If your engine brake isn’t slowing your vehicle down as much as you’d like, it might be running at too low of an RPM. Many drivers and fleet managers complain about weak engine braking, but often, the issue comes from incorrect programming or a lack of knowledge about how to properly use the brake system.

Some fleet managers discourage drivers from using engine brakes at high RPMs, but that’s a mistake. Engine brakes are designed to work best at higher speeds. Some can handle up to 3,000 RPM for long periods under full load without damage. Manufacturers build these brakes to last under normal conditions, so running them at high RPM won’t cause unnecessary wear.

Adjusting Engine Settings for Better Braking

One reason engine brakes might seem weak is that many modern trucks use low-RPM drivetrains. Engine brakes don’t work as well at lower speeds, like 1,200 RPM. To improve performance, drivers might need to shift down one or two gears.

Ideally, a truck’s cruise control should handle these downshifts automatically when extra braking power is needed. However, if the truck doesn’t have an active cruise control system, it may pick up speed on downhill slopes, forcing drivers to rely on service brakes instead.

Some fleets try to solve this by limiting gear choices in automated transmissions to encourage cruise control use. However, this can be frustrating if drivers aren’t comfortable with those settings. Drivers must understand how automated manual transmissions (AMTs) and cruise control systems work together. If they don’t, they might not use the engine brake properly, leading to weaker performance.

What are High Power Density Engine Brakes?

For fleets that don’t want to run engine brakes at high RPM, there’s another option: High Power Density (HPD) engine brakes.

HPD engine brakes are designed for low-RPM engines. Modern trucks use fuel-efficient tires and aerodynamic designs, which reduce natural rolling resistance. Combined with engines running at lower speeds, this means trucks need extra braking help.

HPD brakes use special valve technology to create two braking events per engine revolution instead of one. This nearly doubles the braking power at maximum RPM.

For trucks with low-RPM engines, HPD brakes work as well as standard engine brakes but at lower speeds. This means drivers don’t need to downshift as much to get strong braking performance.

Related Articles: